As we head towards the 50th anniversary of Star Wars and race towards the 50th anniversary of Star Wars action figures, I thought readers would appreciate a deep dive into how those original Star Wars figures were made. In the second of these features, I look at Star Wars silicon moulds. You may wish to check out part one on sculpting before you continue.

As mentioned in the previous article, pre-production items are pretty tough to come by and the silicon moulds are no exception with very few pieces surviving and even fewer images available. The purpose of the silicon mould was to create the hardcopy of the action figure, or accessory, needed to further the development. Wax is too fragile a material to work with and an additional benefit of making silicon moulds of the sculpts is that more sculpts could be made by storing excess wax in the moulds, thus also keeping their shape for re-use if needed.

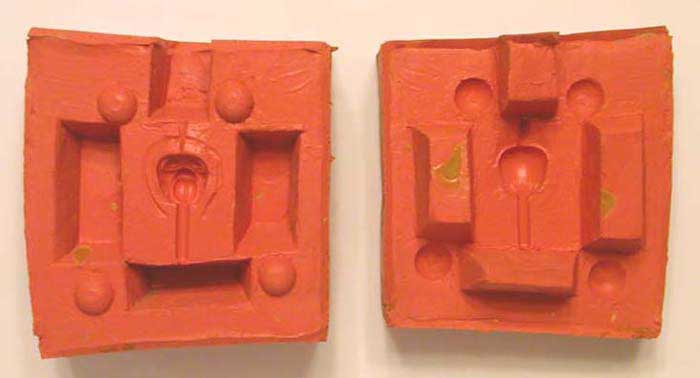

Once the wax or acetate sculpt is completed, then a silicon mould is made. This is created in two halves with a parting line evident where the two moulds would join. Silicon is a pliant material which allows for the easy removal of the hardcopy once cast, but deteriorates after several uses.

Here is the silicon mould for the Rancor Keeper torso. As well as being able to see the imprint of the torso, you can also make out the pins used in the wax sculpt for the joints. There are also three further points of interest. Firstly, at the base, there is a cone or funnel shape known as “the gate” which is needed to pour in the material to make the hardcopy. Secondly, in this image there are positive and negative lines which are known as “keys” which are needed to keep the two halves of the moulds firmly in position. These lock the moulds in a firm position to ensure that a quality hardcopy is produced. As you can see from the Walrusman head below, there are different methods of doing this with rectangular and circular shapes used in this example.

Finally, you will spot that there are also channels or grooves which are needed to allow air or excess materials to escape once the mould is in use. You can see this clearly around the Walrusman head in the image above.

Finally, you will spot that there are also channels or grooves which are needed to allow air or excess materials to escape once the mould is in use. You can see this clearly around the Walrusman head in the image above.

Two moulds are needed for each part of the action figure, as you can see below where the unproduced Ewoks Chief Chirpa consists of 10 separate items. It is truly special that this set is complete and in the hands of a collector today.

![]()

Silicon moulds weren’t designed to last so we are incredibly fortunate to see these still around today. Indeed, head over to theswca to see other wonderful examples of silicon moulds for alternative sculpts which didn’t make it to production.

Photos (c) theswca.com, Ron Salvatore, Gus Lopez, Chris Georgoulias, Tracey Hamilton, Chris Fawcett.

Special thanks to Chris Fawcett and his knowledge on the creation of Star Wars action figures. Any inaccuracies are entirely down to the author.